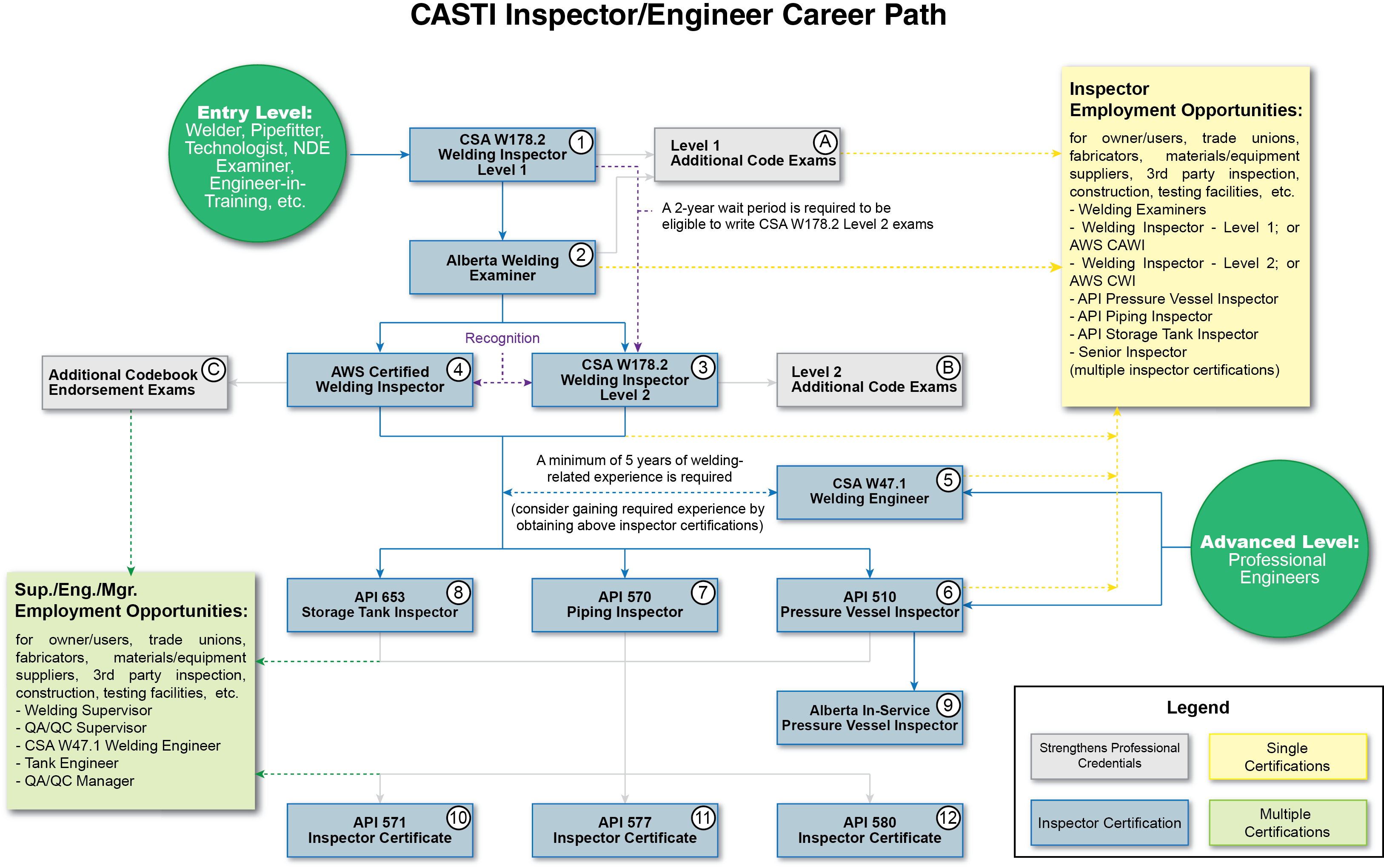

Career Path for Inspectors and Engineers

Lean into our people's expertise

We created our Career Path Service to help our customers plan the most straight forward path to their future.

There are too many variables for everyone to have the exact same path to a specific certification.

As a CASTI customer - when you phone us we will go over

- The work you want to be doing in the future.

- The accreditation you want to have to do the work you are interested in.

- The certificates and work experience you have.

- With this information we will help you plan the most straight forward path to your future.

Information to help you start planning

Welding Inspector/Examiner Career Path

1. The shortest and easiest step to begin a career as an inspector is to obtain the CSA Level 1 Certified Welding Inspector (CWI) accreditation; (see Box A)

Note 1: if code experience is insufficient, it is recommended to take the Introduction to ASME Codes course as the first step*; Note 2: jumping steps in this career path by going directly to the Alberta Welding Examiner (WE) or API Inspector certification programs are much larger steps that require considerable thought before attempting them; please contact CASTI customer support staff for further discussion to assist you with this decision; 2. There is a 2-year waiting period for a CSA Level 1 CWI before challenging their Level 2 CWI exams; during this 2 year period, the Alberta WE certification can be obtained, which typically can take 12 to 18 months; (see Box B)

3.Tthe Alberta WE certification typically takes about 1 to 1.5 years to complete;

4. Since there is some overlap between CSA Level 1 CWI and the Alberta WE

certifications, the individual will be better prepared for challenging the WE program after achieving the CSA Level 1 CWI status, particularly if they have multiple code endorsements;

5. During the 2 year waiting period between the CSA Level 1 and Level 2 CWI programs, the inspector can continue their career development by also obtaining other code endorsement certifications, since CSA W178.2 limits inspection work to the code that was written during the initial examination; (see Box A1)

6. With this career development path, since there is a significant overlap between the Alberta WE and CSA Level 2 CWI programs, the inspector will be better prepared to challenge the CSA Level 2 CWI exams; (see Box D)

7. With the CSA Level 2 CWI certification, by recognition, the inspector can become an AWS CWI; (see Box C)

8. To strengthen professional credentials and create more job opportunities, the inspector can continue their career development by also obtaining other code endorsement certifications, since the AWS CWI and CSA W178.2 certifications limit inspection work to the code that was written during the initial examination; (see Box C1 and D1)

9. After 2+ years with the above CASTI career development path, the individual will have obtained the following three certifications:

|

API Pressure Equipment Inspector Career Path

1. Now that the welding inspector/examiner has experience with various codes and writing exams, the next step in their career development is to follow the API pressure equipment inspector career path, which will be a smoother and more natural progression; 2. The first API inspector step is to become an API 510 Pressure Vessel Inspector since it is mandated in Alberta by the Pressure Equipment Safety Regulation (PESR, which is the law) that only certified in-service inspectors are permitted to inspect pressure vessels, which provides job opportunities; (see Box E) 3. With the API 510 certification, the individual can then write the Alberta In-Service Pressure Vessel Inspector certification exam; (see Box H) 4. Although there are no other PESR requirements for API inspectors, most companies require piping and storage tank inspectors to be certified as:

5. After becoming either an API 510, 570, or 653 inspector, the inspector can further their career development by obtaining the three API advanced knowledge certifications: (see Box E1, E2, and E3)

NOTE: The API 571, 577, 580 Advanced Knowledge Certifications can now be obtained at any time the candidate meets the qualifying requirements and can be taken prior to the basic API certifications (API 510, 570, 653). 1. CSA Level 2 Welding Inspector Although it is not necessary to achieve all of these certifications to be employed as a welding or pressure equipment inspector, the more certifications one can achieve, the more employable they become. |

Getting Started: Alberta Welding Examiner

A Welding Examiner Certificate of Competency authorizes the holder to conduct Performance Qualification (PQ) tests on behalf of a testing organization while employed by that testing organization. All ABSA authorized testing organizations are required to employ a Welding Examiner to conduct performance qualification tests. Education and Experience Requirements

To take a Welding Examiner Certificate of Competency examination, a candidate must meet at least one of the following criteria: a) Professional Engineer with a Bachelor of Science Degree in Metallurgy, Welding, or Mechanical Engineering, or b) First Class Power Engineers Certificate of Competency, or c) Certified Engineering Technologist (CET) with a Diploma in Materials or Mechanical Engineering Technology, or d) Diploma in Welding Engineering Technology, or e) Grade A or B Pressure Welder, or f) Canadian Standards Association (CSA) W178.2 Welding Inspector Level III, or g) Safety Codes Officer Boiler Discipline, or h) Other Equivalent Qualification, as determined by the Administrator

|

Getting Started: CSA W178.2 Level 1 & 2Education and Experience Requirements

CSA W178.2 Level 1 Welding Inspector shall have: b) successfully completed recognized courses in the fundamental principles and practices of welding, quality control, and welding inspection NOTE: Level 1 WI shall perform welding inspection under Level 2 or Level 3 WI or by non- certified personnel who, in the opinion of the CWB, possess the knowledge, skills training, and experience required to perform such supervision CSA W178.2 Level 2 Welding Inspector shall have:

a) min. 2 years of experience as a certified Level 1 welding inspector NOTE: In exceptional cases, practicing welding inspectors may be eligible to qualify directly as Level 2 or Level 3. In such cases, candidates shall demonstrate to the CWB that their combination of education, training, and experience is equivalent to either Level 2 or Level 3. CSA W178.2 Welding Inspector Examinations

Level 1: b) product category code exam; 2 hrs, open (45 multiple choice questions) c) W178.2; 0.5 hrs, open (15 multiple choice questions) d) visual practical; 0.5 hr (10 samples for visual detection and identification) min. grade: 70% total: 5 hrs

b) descriptive report writing; 1 hr, closed (5 essay questions) c) product category code exam; 2 hrs, open (45 multiple choice questions)

total: 7.0 hrs

b) ABS c) CSA S473 e) CSA Z662 f) ASME VIII-1 and IX g) API 650 Renewals

Levels 1, 2, 3: - 3 years reapply - 6 years re-exam; written exam(s) on certified code(s) Reciprocity and RecognitionFrom CSA to AWS From AWS to CSA * must write a 0.5 hr open-book W178.2 exam NOTE: When applying as an AWS CWI for CSA W178.2 Recognition, you will be permitted to inspect the equivalent code endorsement(s) for which you wrote your AWS CWI exam. |

Getting Started: AWS Certified Welding InspectorEducation and Experience RequirementsAssociate Welding Inspector shall have: a) high school graduate and b) min. of 2 years of qualified experience with welding fabrication and standards and directly involved in 1 or more qualified areas; or c) an eighth grade level of schooling with a minimum of 4 years work experience in 1 or more qualified areas; or d) alternatively, 2 years post-high school education in welding curriculum or engineering technology, engineering, or physical sciences, and a min. of 6 months experience in any of the welding functions NOTE: CAWI shall perform inspections under the active supervision of a CWI or SCWI

a) high school graduate and b) min. of 5 years of qualified experience with welding fabrication and standards and directly involved in 1 or more qualified areas; or c) an eighth grade level of schooling with a minimum of 9 years work experience in 1 or more qualified areas; or d) alternatively, max. of 2 years of post-high school education may be substituted for an equal number of years of the required 5 years experience, as follows: i) eng., eng. tech., or sc. degree; 2 years max. ii) eng. or eng. tech. courses; 2 years max. iii) trade/vocational courses related to welding; 1 year max. NOTE: the areas of qualified experience options are listed in AWS B5.1 paragraph 5.5

|

Getting Started: API 510 Pressure Vessel Inspector

API's Inspector Certification Programs are based on industry-developed standards that are recognized and used with confidence worldwide. These standards have also provided a uniform platform that serves as a model for many state and government regulations. These API programs emphasize professional credibility and process integrity. They enable inspectors to play an active role in improving industry health and safety; environmental performance; ensuring compliance and self-regulation; and strengthening management control and internal inspection capabilities.

Education and Experience Requirements

To take the API 510 examination, a candidate must meet at least one of the following criteria: API 510 Pressure Vessel Inspector Examination

The exam candidate must bring the applicable API & ASME reference publications listed on the Effectivity Sheet pertaining to the API 510 exam for the open-part of the examination The examination consists of two parts. API 510, Pressure Vessel Inspection Code B. ASME Publications: Section V, Nondestructive Examination NOTE: Refer to the Publications Effectivity Sheet in the application package for a list of specific editions, addenda, and supplements of the reference publications that are effective for your exam date. All API and ASME publications are copyrighted material. Photocopies of publications are not permitted at the exam. These code documents can be purchased from CASTI. Renewals

- every 3 years, reapply |

Getting Started: API 570 Piping Inspector

API's Inspector Certification Programs are based on industry-developed standards that are recognized and used with confidence worldwide. These standards have also provided a uniform platform that serves as a model for many state and government regulations. These API programs emphasize professional credibility and process integrity. They enable inspectors to play an active role in improving industry health and safety; environmental performance; ensuring compliance and self-regulation; and strengthening management control and internal inspection capabilities.

Education and Experience Requirements

To take the API 570 examination, a candidate must meet at least one of the following criteria: API 570 Piping Inspector Examination

API examination consist of 150 multiple choice questions.

The examination consists of two parts. The closed-book part tests the candidate on knowledge and tasks requiring everyday working knowledge of The open-book portion of the examination requires the use of more detailed information that the inspector is expected to be able to find in the documents, but would not normally be committed to memory. A. API Publications: B. ASME Publications: NOTE: Refer to the Publications Effectivity Sheet in the application package for a list of specific editions, addenda, and supplements of the reference publications that are effective for your exam date. All API and ASME publications are copyrighted material. Photocopies of publications are not permitted at the exam. These code documents can be purchased from CASTI. Renewals- every 3 years, reapply |

Getting Started: API 653 Aboveground Storage Tanks Inspector

API's Inspector Certification Programs are based on industry-developed standards that are recognized and used with confidence worldwide. These standards have also provided a uniform platform that serves as a model for many state and government regulations. These API programs emphasize professional credibility and process integrity. They enable inspectors to play an active role in improving industry health and safety; environmental performance; ensuring compliance and self-regulation; and strengthening management control and internal inspection capabilities.

Education and Experience RequirementsTo take the API 653 examination, a candidate must meet at least one of the following criteria:

|

Getting Started: Alberta In-Service Pressure Vessel Inspector

In Alberta, pressure equipment owner-users must have an Integrity Management System (IMS) that complies with the Alberta Pressure Equipment Safety Regulations (PESR). In compliance, all IMSs require personnel who inspect and certify installed pressure vessels, boilers, fired equipment and similar equipment, and those who supervise in-service inspection staff, shall hold the required Alberta In-service pressure equipment Inspector Certification and be certified as competent to perform the specific type of inspection.

|

Getting Started: API 571 Certification

Certification Program for Advanced Knowledge of Corrosion and Materials

The objective of this Certification program is to provide documented evidence of advanced knowledge and expertise in the area of Corrosion and Materials based on the information contained in API RP 571. Education and Experience Requirements

API 510

|

Getting Started: API 577 Certification

Certification Program for Advanced Knowledge of Welding Inspection and Metallurgy

The objective of this Certification program is to provide documented evidence of advanced knowledge and expertise in the area of Welding Inspection and Metallurgy based on the information contained in API RP 577.

|

| Education | Experience |

| Engineering Degree 2-Year Technical Degree High School No Formal Education |

1 year of experience in petrochemical industry 2 years of experience in petrochemical industry 3 years of experience in petrochemical industry 5 years of experience in petrochemical industry |

Or have a valid and current basic API certification as one of the following:

API 510

API 570; or

API 653

API 577 Inspector Examination

- API 577 examination consist of 70 multiple choice questions

- It is a 4-hour closed-book exam

- No reference materials will be permitted at the examination

- This examination has a set passing point of 70%, or 49 correctly answered questions

The examination will be based on the API Recommended Practice 577 – Welding Inspection and Metallurgy

NOTE: Questions become effective when the applicable API documents (namely API RP577 – any new issue, addenda or rewrite) have been in use for 12 months since issue date. This code documents can be purchased from CASTI.

Renewals

- every 3 years, reapply

Getting Started: API 580 CertificationCertification Program for Advanced Knowledge of Risk-Based Inspection

The objective of this Certification program is to provide documented evidence of advanced knowledge and expertise in the area of Risk-Based Inspection (RBI) based on the information contained in API RP 580.

|

| Education | Experience |

| Engineering Degree 2-Year Technical Degree High School No Formal Education |

1 year of experience in petrochemical industry 2 years of experience in petrochemical industry 3 years of experience in petrochemical industry 5 years of experience in petrochemical industry |

Or have a valid and current basic API certification as one of the following:

API 510

API 570; or

API 653

API Inspector Examination

- API 580 examination consist of 70 multiple choice questions

- It is a 4-hour closed-book exam

- No reference materials will be permitted at the examination

- This examination has a set passing point of 70%, or 49 correctly answered questions

The examination will be based on API Recommended Practice 580 – Risk-Based Inspection.

NOTE: Questions become effective when the applicable API documents (namely API RP580 – any new issue, addenda or rewrite) have been in use for 12 months since issue date. This code documents can be purchased from CASTI.

Renewals

- every 3 years, reapply

Call to action

| Download Career Path Guide | Phone us - or email us? |